AT FIRST, the small glass box simply whirs.

Then, with a small wheeze, a nozzle arm jerks to attention and begins to move back and forth. After a few minutes, a shape begins to emerge as layer after layer of melted plastic filament is applied. After about quarter of an hour, the machine quits with a pop, and the window sits a bright red...thingie.

“It’s basically an all-purpose kitchen gadget,” explains industrial designer Ty Donaldson as he takes it out, demonstrating how the sturdy three-inch tool can stack soda cans and clip shut a bag of potato chips.

The red gizmo is just a small, simple example of what a portable-sized 3D printer can do, Donaldson explains to a small group gathered for a recent lunch ‘n’ learn at the Savannah Coffee Roasters. Some are familiar with the technology, others are witnessing the “magic” for the first time.

Armed with a breadbox-sized MakerBot Replicator 2 courtesy of local IT sales and service provider LSP Technologies, Donaldson and business partner Tim Cone are here to demystify the concept of 3D printing —and get people of all ages designing and making their own gadgets.

Donaldson and Cone founded their start-up company Maven Makers in 2013. With the mission of helping others gain new skills, they took their name from futurist Malcolm Gladwell, who popularized the Yiddish term for “accumulator of knowledge” in his influential book, The Tipping Point. Gladwell suggests a true “maven” is not only an expert on something, but someone willing to share the wisdom in order to benefit the greater good.

These guys certainly qualify. With combined backgrounds in engineering, education, manufacturing, robotics and good old-fashioned garage tool usage, the team has hosted local workshops in basic wood shop, metal work and digital fabrication.

“This is trending right now. People want to have these types of skills,” says Donaldson, a SCAD grad who manages Rapid Prototyping services in the campus lab.

“With our classes and camps, we want to foster a culture of creativity.”

The Maven Makers’ ultimate goal is to create a “makerspace,” where anyone can pay a monthly membership fee and have access to machines, tools and expertise to complete their individual projects. Fundraising efforts are underway, and in the meantime, the inventive duo is taking the show on the road with summer camps at the Boys & Girls Club in Hilton Head and workshops at Georgia Southern’s Fab Lab.

Locally, more classes are planned for schools and the general public. Collaborations are in the works with Telfair Museums as well as the Guild Hall, the gamers’ paradise on Montgomery Street that has its own makerspace and 3-D printer. With their wealth of technical know-how, the mavens hope to help along those already in possession of the tools.

“We’d like to be the facilitators of the maker movement in the Coastal Empire,” affirms Cone, named a 2014 Teacher of the Year finalist for his work with manufacturing, robotics, and engineering students at Woodville Tompkins High School.

“We see a real need here. People want to make things for themselves.”

As the advent of 3-D printing has gone from science fiction to reality in the space of a nanosecond, the technology has tremendous appeal for non-engineering types. Prices on personal-sized equipment are plummeting, and decent 3-D printer can be had for under $1000. The MakerBot model used by the Maven Makers runs about $2800, though industrial versions can run more than a half million dollars.

There are also scanners that read an object and create a blueprint, a useful tool when trying to replicate a broken part.

“That little round part in the middle of your microwave? Impossible to fix if it breaks,” Donaldson tells the group. “Now you can just make it yourself.”

But don’t expect it all to work right out of the box. Creating the design, calibrating it correctly and feeding the filament all take practice, and more often than not, guidance.

“This isn’t necessarily easy stuff to learn,” confesses software designer James Sentman, who came to the lunch ‘n’ learn for tips on using his home 3-D printer.

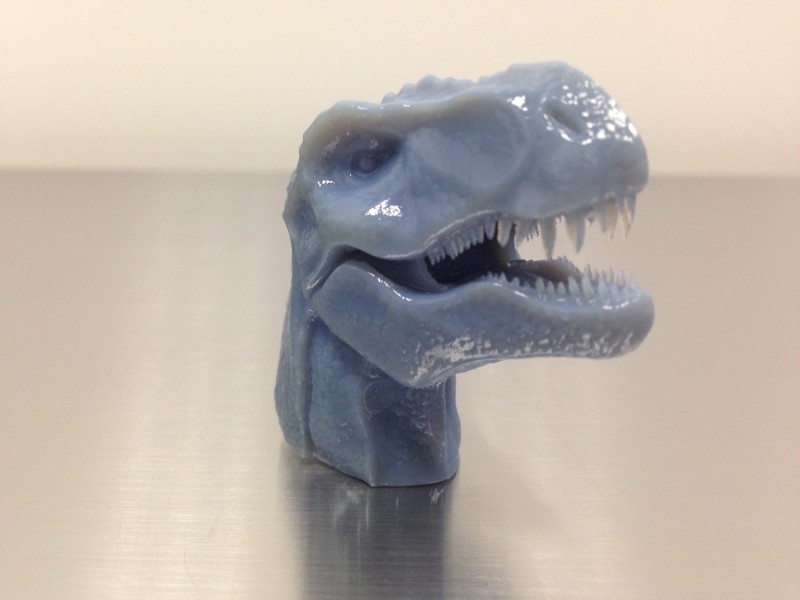

Those with advanced knowledge can use open source software to create an original model; others can download free designs for all kinds of doodads from sites like Tinkercad and Thingiverse. While Donaldson and Cone used simple examples like the red kitchen tool and dragon heads in their workshop, they remind that the innovations extend far beyond toys and tsotchkes.

“This is transforming the medical and dental industries. Instead of waiting weeks for an implant, it can be designed and done in a matter of hours,” says Cone.

Hearing aids, car parts and USB phone chargers barely cover the possible items that could be produced in one’s own living room. NASA is testing ways to print equipment on the moon in advance of astronauts’ arrival. Closer to home, May Howard Elementary students recently helped design a prosthetic leg for Oatland Island resident Stumpy the Turtle.

The materials aren’t limited to plastic and rubber, either: You may soon make dinner out of 3-D printed steaks and pasta layered up in crazy shapes.

And in the realm of completely mind-blowing meta, you can use a RepRap 3-D printer to print...another 3-D printer.

Controversy remains over copyright infringement possibilities, loss of mass manufacturing jobs and 3-D printed guns. But for the Maven Makers, 3-D printing means anyone’s creative potential is only limited by his or her imagination—after you’ve found a printer and figured out how the dang thing works.

“This technology has actually been around for a while,” says Donaldson.

“The key now is access—and teaching people how to use it.”